Our Services

We can quickly create prototype of your product and start production of low volumes of products and you will be able to demonstrate the appearance and functionality of the product and launch it to the market. We can produce it in both simulated and actual materials, so that you could estimate it.

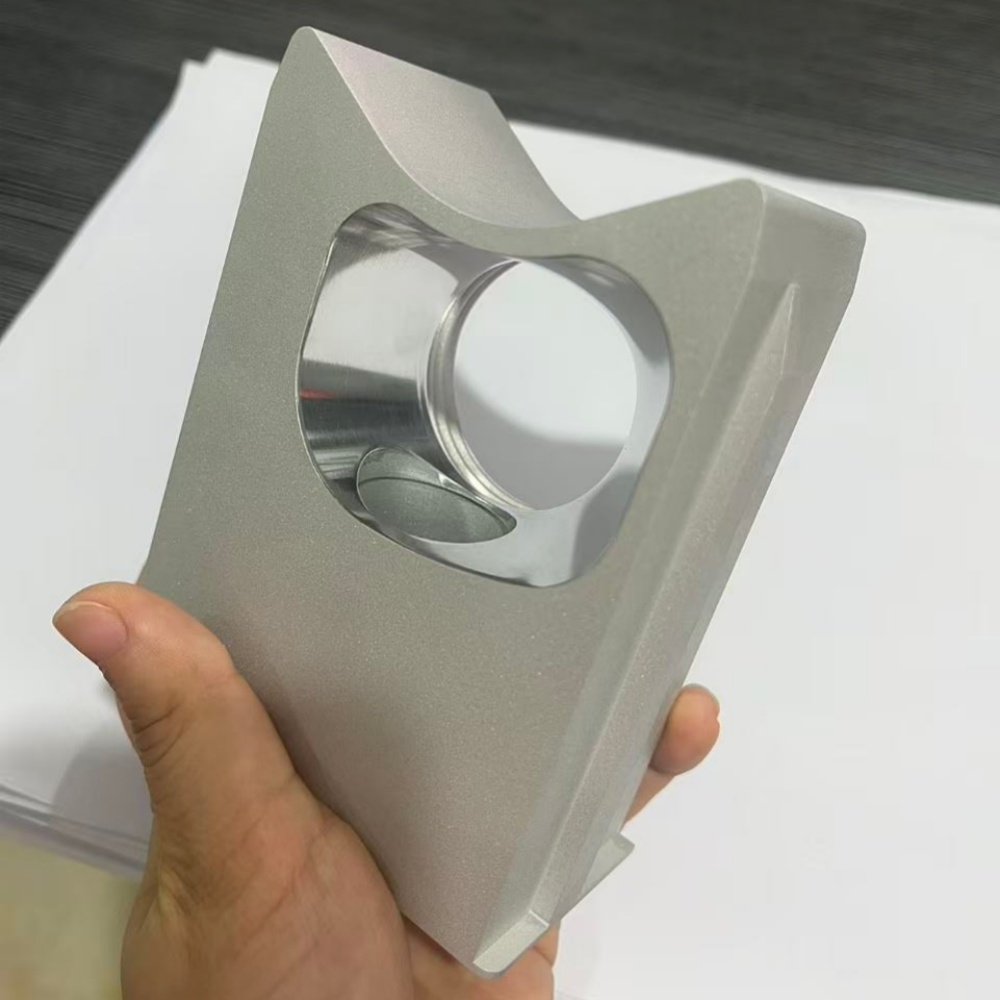

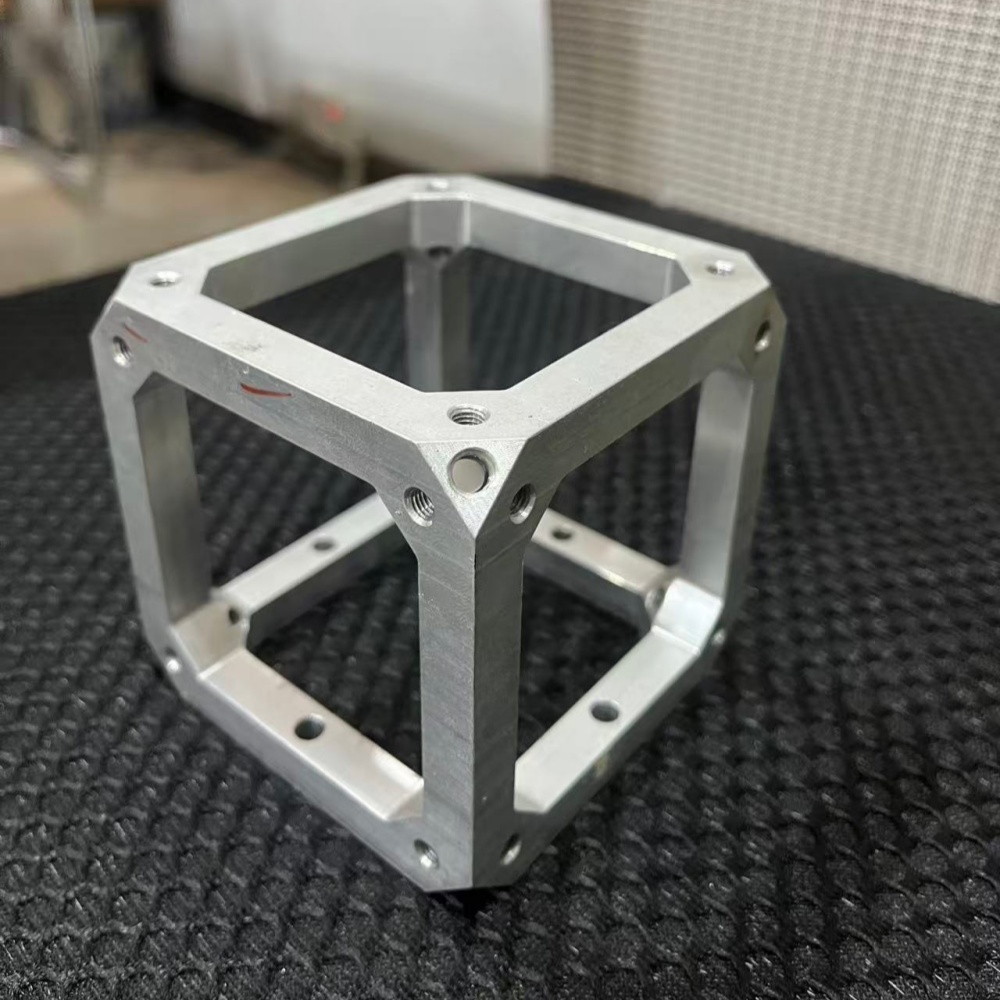

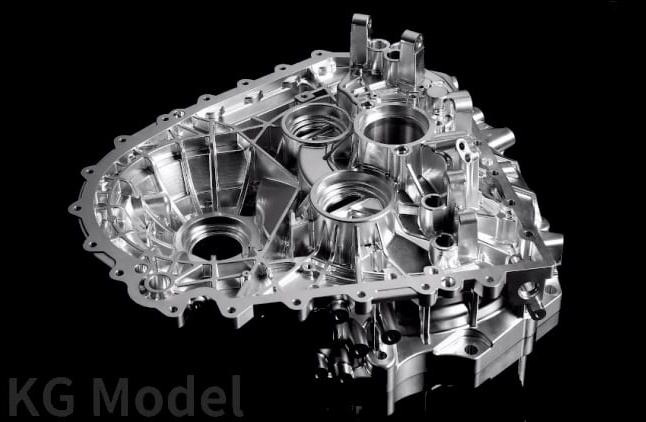

CNC Machining

Using real production materials instead of simulated ones, it achieves high precision and replication capabilities in a short time.

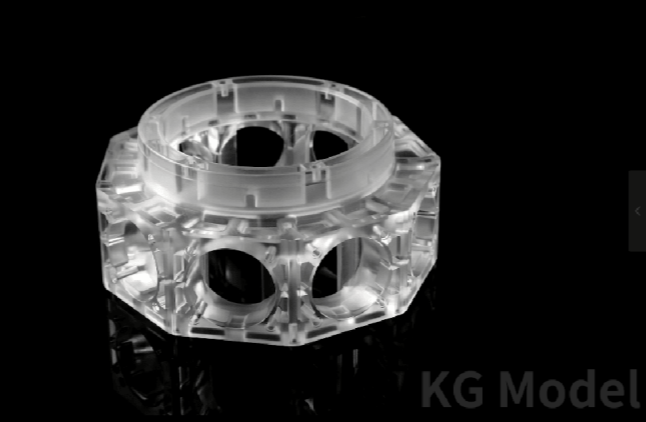

Vacuum Casting

This process utilizes silicone molds, making it well-suited for low-volume production with lower costs for larger prototype batches.

Sheet Metal Stamping

Prototypes and small-batch parts are typically made via CNC or laser cutting, allowing for shorter lead times and efficient production.

3D Printing

Great for design testing. There are some limitations with material selection although high detail and complexity can be achieved with the quickest lead time.

Injection Moulding

Best for cases requiring specific plastic grades or low-volume production, this method suits larger parts and intricate designs.

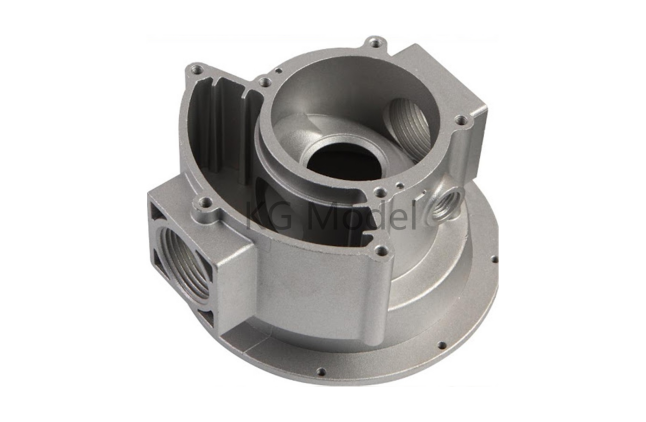

Metal Die Casting

A widely used process, it provides stable and durable molds, making it ideal for high-volume production with repeated casting needs.

Rapid Prototyping and Low-Volume Manufacturing

Shenzhen KG Model provides high-quality 3D Printing, CNC Machining, Vacuum Casting and other services. We manufacture metal and plastic parts for international customers in automotive, medical, consumer, aerospace and other industries. We put together professional team of engineers, technicians and sales managers, who deliver high quality service to our clients.

Rapid Prototyping

Rapid prototyping is a group of techniques used to quickly produce a scale model of a physical part or assembly using three-dimensional CAD data. Construction of the part or assembly is usually done using 3D printing or additive manufacturing technology.

Low-Volume Manufacturing

Have your low-volume manufacturing parts made fast. We can make up to 500+ parts either one time or on a regular basis. Manufacturing in low volumes is an ideal solution for managing your inventory and testing the market before producing larger quantities.

Shenzhen KG Model Co., Ltd.

At Shenzhen KG model we specialize in the production of high-quality prototypes and models, made at a great price. Having successful experience of manufacturing products for various industries, we are perfect one-stop solution for your prototyping needs.

When you need low-volume manufacturing, we will be glad to provide it. Our main services include 3d printing, cnc machining, pu and metal casting, sheet metal stamping and injection moulding. We support you every step of the way, from initial request to product delivery. Contact our friendly team to get a quick quote for your next project today.

All uploads are secure and confidential

WHAT PEOPLE SAY ABOUT US

“We received your CNC part for the tray. It is perfect! Thank you for your teams great work!”

“Received the HUB parts this morning. First impressions are that they look very good. Many thanks”

“I’m very pleased with the quality of the work – many thanks”

Shenzhen KG Model provides high quality service for various industries including Automotive, Medical equipment, Consumer and Home Appliances, Heavy equipment, Sports equipment, Aerospace/Military.