3D Printing

3D Printing

Our latest 3D printers help to make various kinds of 3D printing parts in plastic and metal material in short turnaround.

3D Printing(SLA, SLS, SLM)

3D printing or additive manufacturing technology is one of the most effective ways to produce complex parts, that machining would not be able to accomplish at an impeccable quality. You are able to get detailed physical copies of CAD designs using our first-rate 3D printing technology. Shenzhen KG Model has Selective Laser Sintering (SLS), Stereo Lithography Apparatus (SLA) machines & Selective Laser Melting(SLM), using 3D data in .stl or .stp file format. They are perfect for your first functional model.

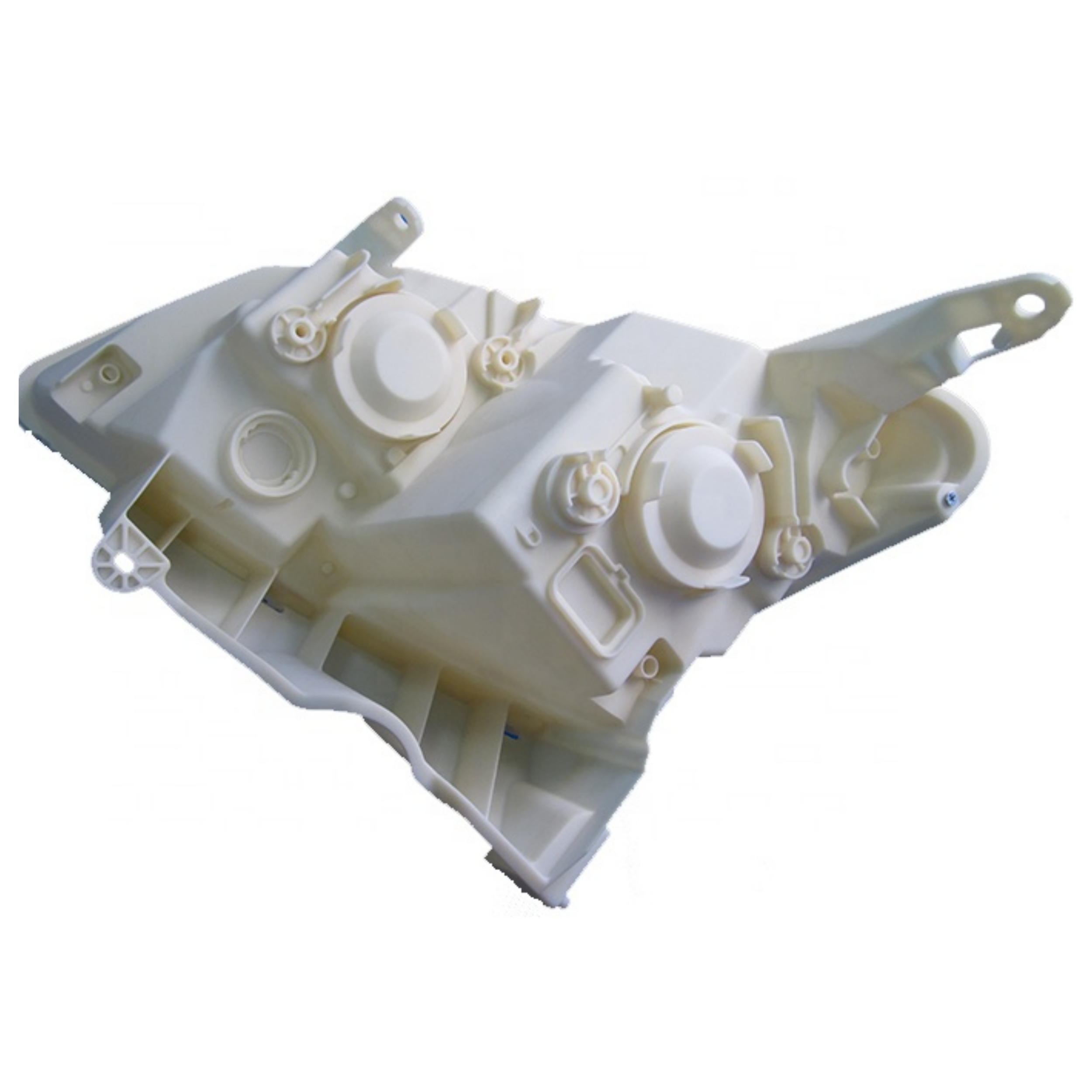

SLA Printing

SLA printing is a layering process, the material is lique and then cured by ultraviolet light. Using CAD data either submitted by you or created in-house, the selected materials. SLA 3D printing offers extremely elevated levels of precision and accuracy on even small prototypes.

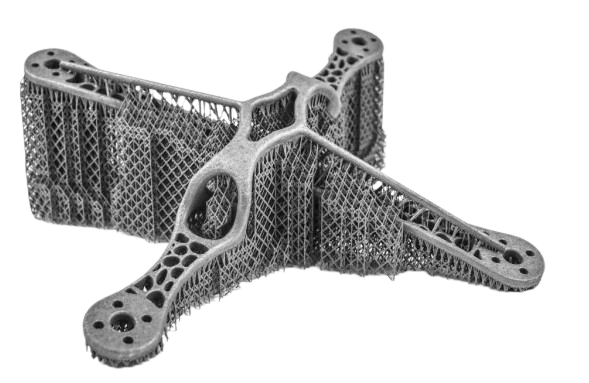

SLS Printing

SLS laser rapid prototyping is a layering process used for producing fully-functional prototypes. In 3D SLS printing CAD designs are divided into equal digital layers which are printed and moulded together using lasers.

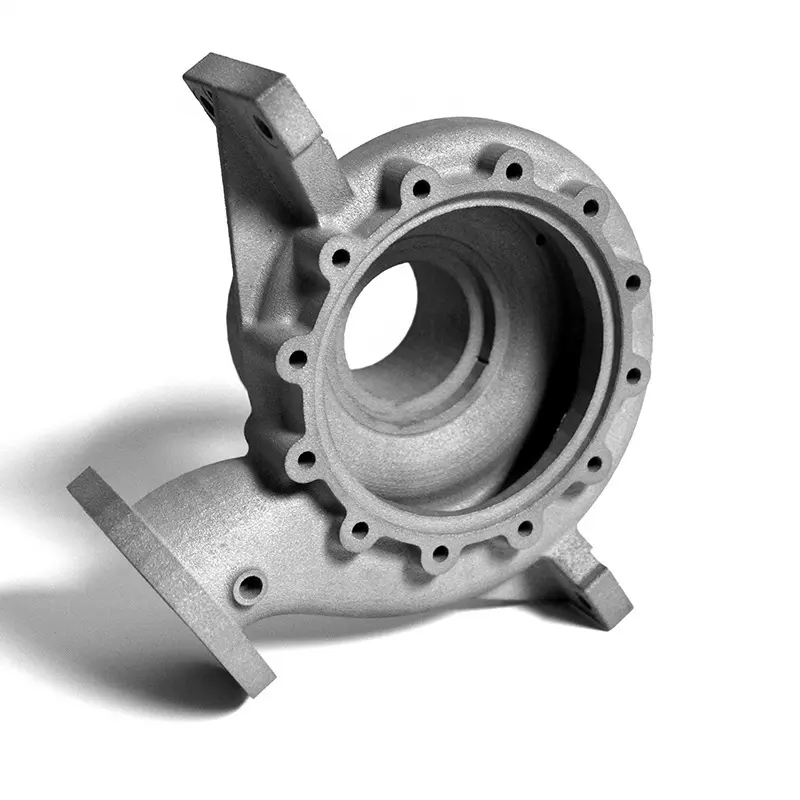

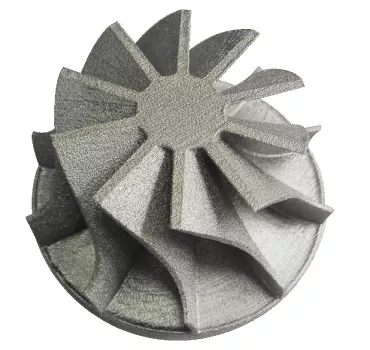

SLM Printing

SLM printing is a 3D printing technique that uses a laser to melt metallic powder into 3D objects, layer by layer.Metal powder is applied to a printing bed and heated with a laser beam from above. The laser melts the powder and bonds it to the previous layers.

Material

For SLA processing: ABS Like, Photosensitive resin.

Color: Beige, White, Black, Transparent. Other colors can by painting.

For SLS processing: Nylon, Nylon+GF

Color: Beige, White, Black. Other colors can made by painting.

For SLM processing: Aluminium, stainless steel,Titanium

Quantity & Lead time

Volume: 1 – 100 pcs

Working time: 3 – 7 working days

Tolerance

The min tolerance can be +/- 0.05 mm.

General tolerance is +/- 0.1mm.