Vacuum Casting

Vacuum Casting

We manufacture vacuum casting parts in low volume in the shortest time.

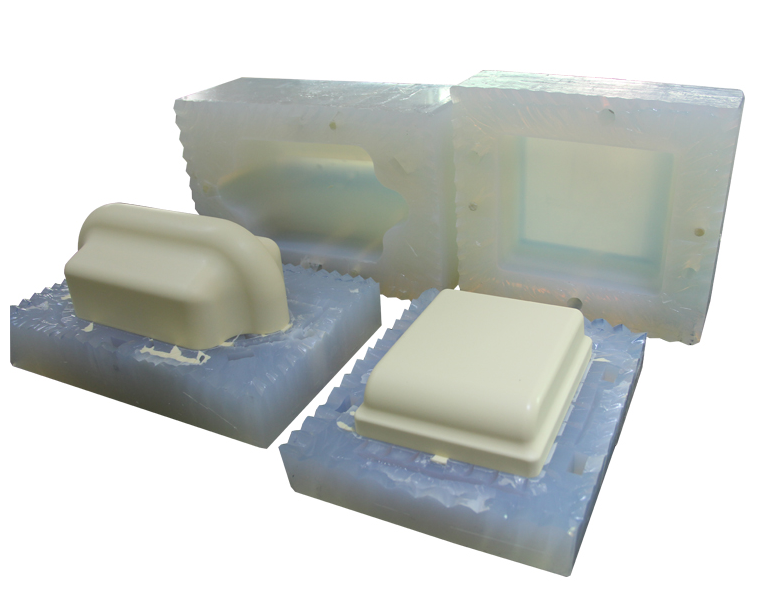

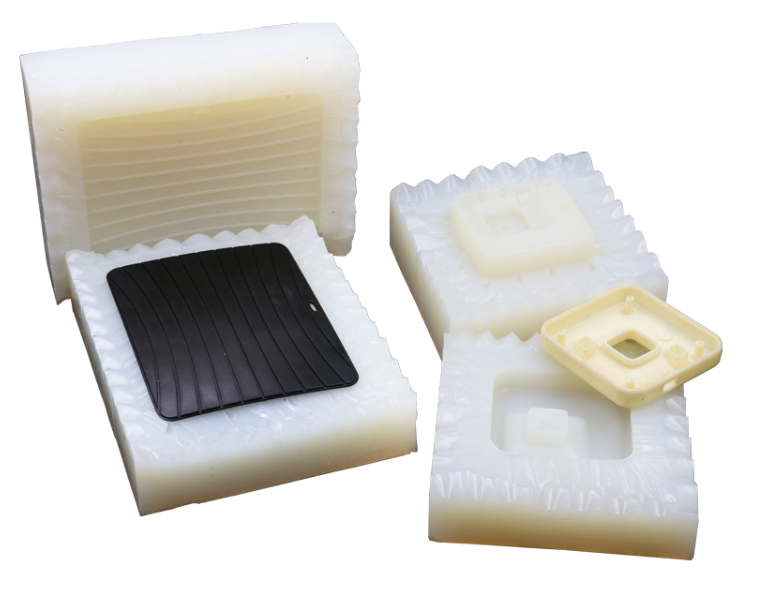

VACUUM CASTING

Vacuum forming is used to create duplicate prototypes and models.

We start by producing a piece (master model) by CNC machining or SLA, and then a silicon rubber mold is used via vacuum casting to produce accurate duplicates of the original piece.

Silicone mold can be reused, making vacuum casting is the perfect choice for small batch production.

Material and Quantity

Material: PMMA, ABS, PC, Nylon and other plastics

Volume: 1 – 100 parts

Tooling time: 5 – 12 working days

Tolerance

The min tolerance can be +/- 0.05 mm.

General tolerance +/- 0.1mm.