About Us

About Us

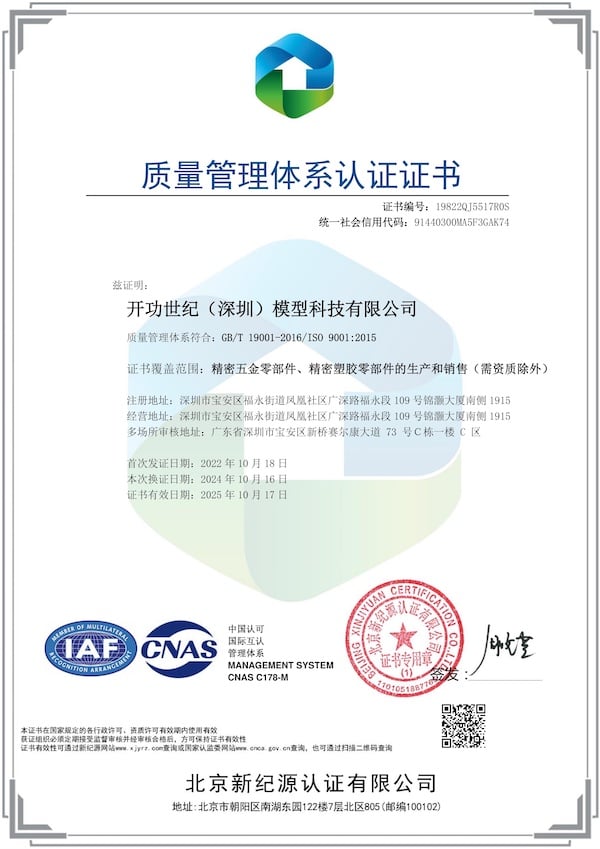

KG Model is a leading rapid prototyping and CNC machining company. And we passed the ISO:9001 qualification.

Our core services include CNC machining, casting PU, rapid prototyping and injection moulding. We have brought together qualified international team of engineers, technicians and sales managers to create top notch products for our international customers. We are a division of Shenzhen GS Model and we have a large factory over 10000 sq.m. with capacity to produce wide range of products for our clients. We offer customized solutions from metal and plastic for different markets since 2008 and have end customers like Land Rover, Panasonic, Philips and Gree.

We strictly respect confidentiality of every client.

Work & Life

At KG Model, we are committed to creating a space that promotes professional development while caring about personal happiness. Here, we are like a close-knit family, moving towards success together.

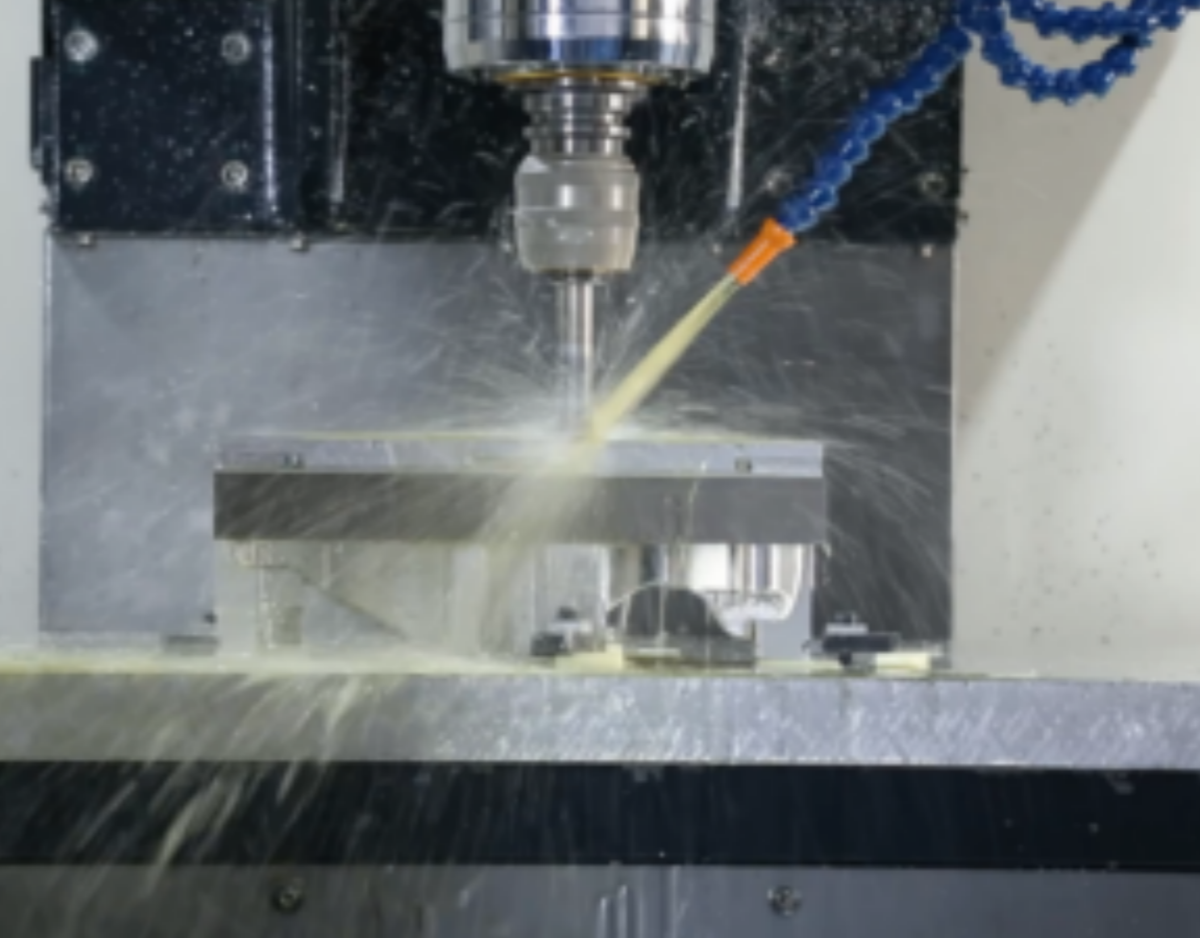

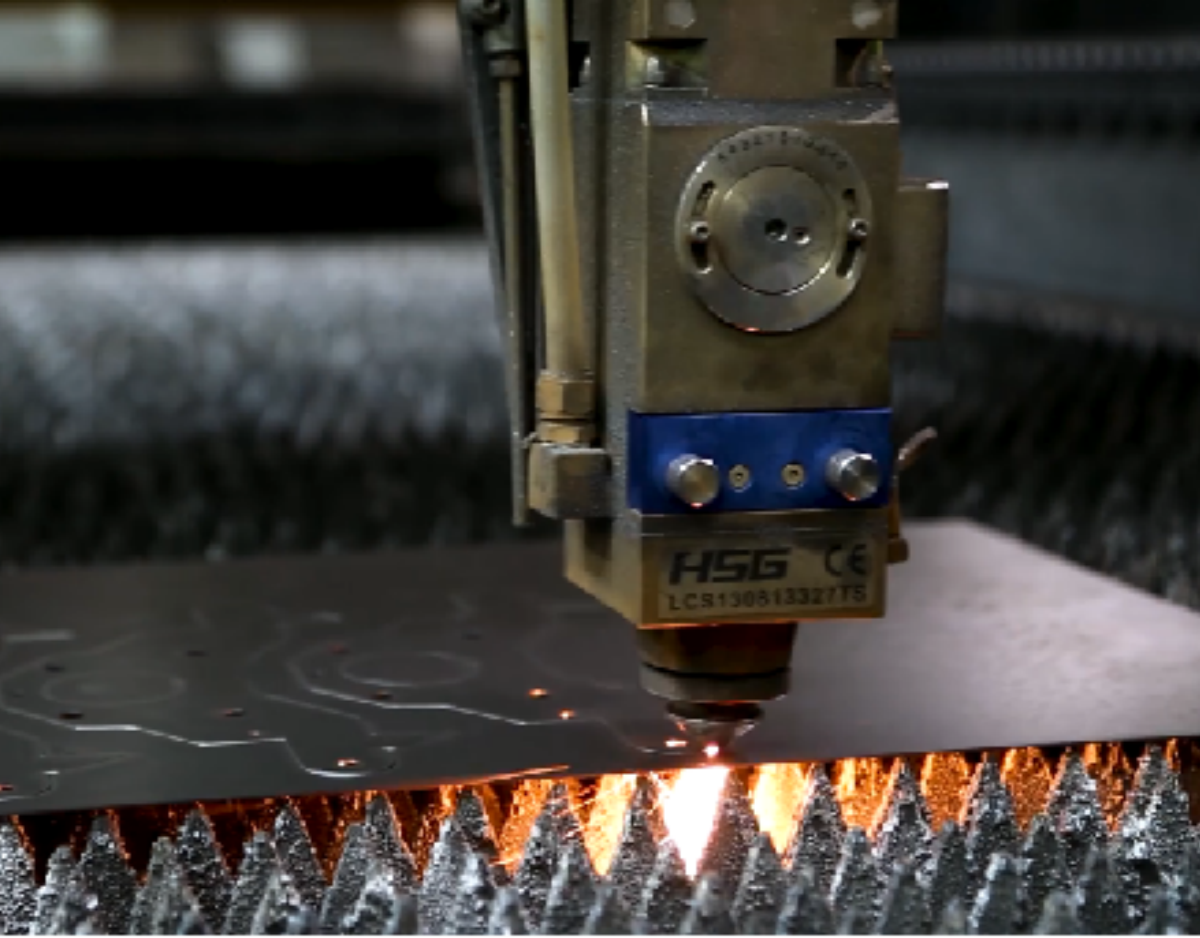

Modern equipment combined with professionalism of our employees

guarantees high quality of our products

Why choose us?

At KG, we have the ability to meet your needs as quickly as possible. We offer various processing methods, use materials that meet the requirements, and have very short lead times. We can also provide professional advice. We also have the following advantages:

Quality Assurance

We implement a comprehensive quality management system (QMS) that covers every aspect from raw material procurement, processing to final inspection. Our quality control includes strict raw material inspection, precise processing control, and final product inspection.

We have passed the ISO9001:2015 quality management system certification. Our team is proficient in various materials and complex processing techniques, and can handle various needs from small batch customization to large-scale production.

How Does Your Projects Run?

Provide drawings

Send us the drawings in both 2D & 3D format, like PDF, DWG, STP, SLD, IGS, etc. So that we can make a quote for you.

Make A Deal

You give a confirmation on the quote, and we finally confirm everything is OK.

Start Manufacturing

We will start the project after the receipt of the PO or deposit. During the process, we will keep you posted.

Parts inspection

When the parts are done, they will be sent to our Quality Inspection Department to do the inspection, including the appearance, dimension, tolerance, holes, assembly and others.

Parts packing

When the parts are finished inspection, they will be sent to our Packing Department for packing. Pack in carton box or wooden boxes to protect the parts.

Parts To Be Shipped

When the parts are ready to be shipped, we will inform you and send some pictures for your reference.

Delivery Notice

When the parts are delivered, our team will check and confirm with you.

Our achievements