CNC Machining

CNC Machining

With the MOQ of 1 PC, we use the state-of-the-art technologies to make the required prototypes quickly and precisely.

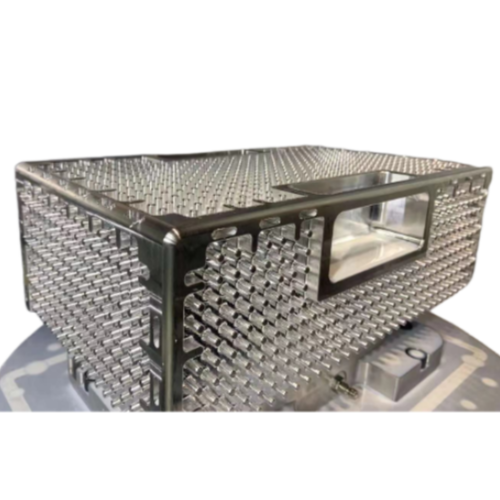

CNC MACHINING

CNC machining is a subtractive manufacturing process, where raw material is removed with a variety of precision cutting tools to make a part or product – milling, turning, EDM and wire EDM, and surface grinding. With our precision 3, 4 and 5-axis CNC machining centers, combined with advanced facilities and experienced team, we can handle all technical aspects of creating your prototype and parts.

We have 88 machines in total. The max product dimension we can machine is 2200*1200*750mm.

Material and quantity

Metal: Aluminum, Steel, Stainless Steel, Titanium, Zinc, Copper, Brass and others.

Plastic: ABS, PC, ABS+PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK and others.

Volume: 1 – 100 parts.

Lead Time: 5-30 days.

Tolerance

The most precise tolerance for steel and aluminium parts made by our CNC is +/- 0.02 mm.

Min tolerance for fine holes is +/- 0.005 mm.

General toterance is +/- 0.1 mm.